|

Suspension Components

|

In vehicle suspension systems, four major types of springs

are utilized. These are coil springs, leaf springs, air springs and

torsion bars. These springs support the weight of the vehicle and its

load, and absorb road shocks. Generally, suspension springs are made of

spring steel to produce high elasticity in the form of plates (leaf

springs), coils or bars. Various suspension systems use different types of

shock absorbers but their purpose is the same, which is to dampen spring

oscillation. Other components within the suspension system and their

specific functions also have profound influences on overall vehicle

performance. |

Coil Spring Coil SpringThe coil spring is made from a length of round spring steel wound into a coil. Coil springs can be used in both front and rear suspension. Some coil springs are formed from a length of tapered steel rod, giving the spring a variable rate. This means that as the spring is compressed, its resistance to further compression is increased. |

Leaf Spring |

Air Spring The air spring consists of a rubber cylinder which is filled with air. A plastic piston located on the lower control arm moves up and down with the lower control arm, causing the compressed air to provide spring-like action. A valve at the top of the rubber cylinder opens to take in or release air, depending upon the vehicle load conditions. |

Torsion Bar |

A shock absorber is a tubular air or hydraulic device mounted near each wheel. It can be mounted separately or inside a shock-absorber-and-strut assembly. Mounted either way, both types work toward the same end, that is to dampen the spring action over rough road surfaces to smooth out the ride. Some shock absorbers are adjustable, either manually or electronically, to different settings. |

Stabilizer Bar |

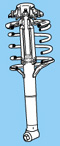

Strut StrutA strut is a rod or tube that is acted upon by side forces or compression forces. A suspension that combines usage of a shock absorber with a coil spring is called a McPherson strut. With this type of assembly, only a lower control arm is required. The top end of the strut is mounted to the body and the bottom is attached to the rear-wheel spindle or to the front-wheel steering knuckle. Separate mountings for the spring and shock absorber are not required. |

Ball Joints A ball joint provides a pivoting joint that attaches the steering knuckle to the control arms, which can only move up and down. The flexible ball-and-socket is mounted in the outer ends of the front suspension control arms. |

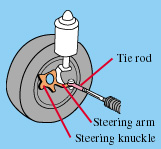

Tie Rod, Steering Arm and Steering Knuckle Tie Rod, Steering Arm and Steering KnuckleThe tie rod, a component of the steering system, is an adjustable-length rod that transfers the steering force and direction from the rack or linkage to the steering arm as the steering wheel is turned. The steering arm attaches to the steering knuckle, and has the tie rod end attached to it. Its function is to turn the knuckle and wheel in and out for steering. The steering knuckle is a component that includes the spindle, on which a front wheel is mounted and which can be turned for steering operations. It is supported by the wheel and upper and lower ball joints, or a lower ball joint and upper strut mount. |

|

Copyright(C) 2000 MITSUBISHI MOTORS, All Rights Reserved.